Welding Nozzle

Price 450 INR/ Piece

MOQ : 100 Pieces

Welding Nozzle Specification

- Standard

- Industrial Grade Copper

- Color

- copper

- Mounting Type

- Handheld or torch mount

- Usage

- Industrial use

- License Free

- No

- Product Type

- welding nozzles

- Material

- Copper

- Size

- Standard/Custom as per requirements

- Operating Mode

- Continuous

- Technology

- Conventional Thermal Welding

- Special Features

- Copper Welding Nozzle

- Application

- Industrial Welding, Soldering, Brazing

- Power Supply

- Manual, No electrical power required

- Compatibility

- Suitable for MIG/MAG/TIG torches (varies by model)

- Maintenance

- Easy cleaning and reusability

- Durability

- High resistance to heat and spatter

- Weight

- Depends on size and specification

- Hardness

- Medium (as per custom specification)

- Shape

- Cylindrical/Conical (varies by design)

- Thermal Conductivity

- High

- Surface Finish

- Polished

- Corrosion Resistance

- Excellent

- Packaging Type

- Box or custom as requested

Welding Nozzle Trade Information

- Minimum Order Quantity

- 100 Pieces

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About Welding Nozzle

- Nozzle Orifice Diameter:0

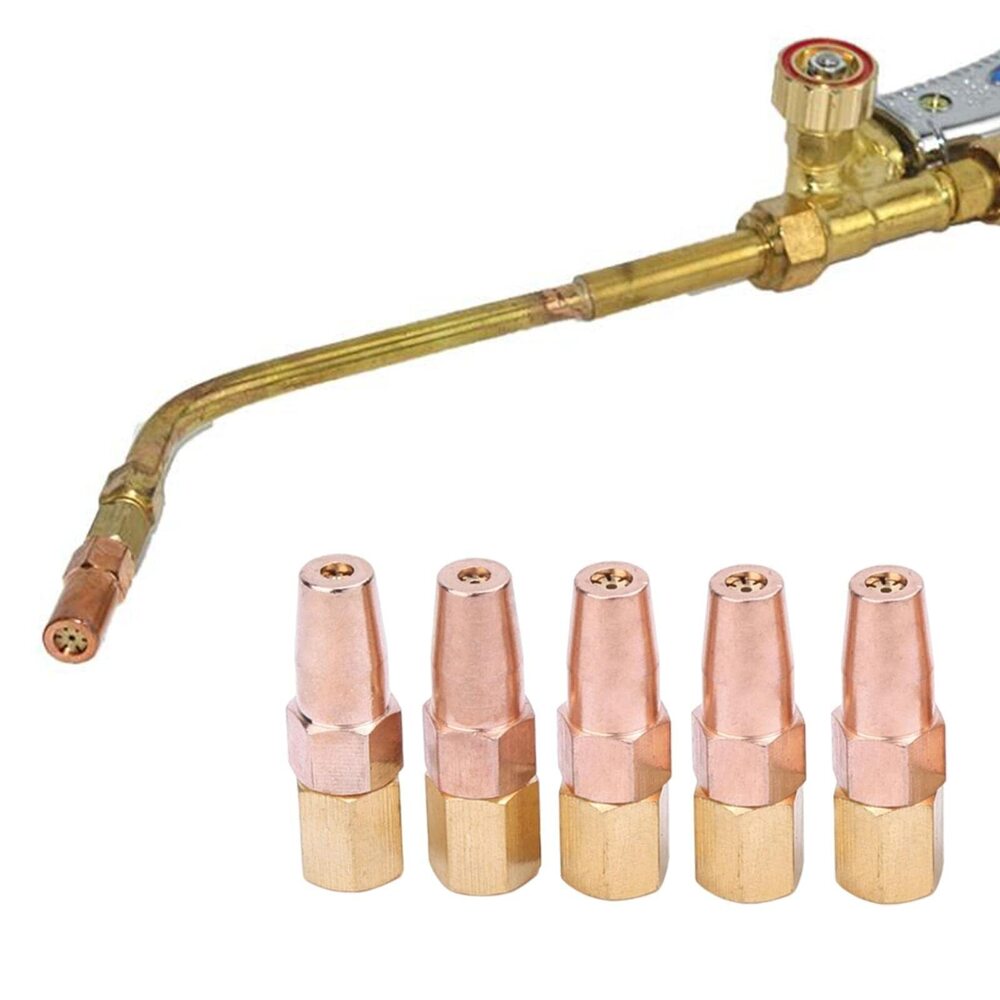

- Size: Height, App.36Mm/1.41Inch. Top Diameter App.11Mm /0.43Inch, Bottom Diameter, App.8Mm/0.31Inch.

- With Heating Head: For Heat Treating, Straightening And Priming Applications.

- Function: Nozzle Used To Protect The Quality Of Your Welds And The Life Of Your Spool And Pull S.

- Application: Ideal For Heat Treatment, Metal Bending, Thermal Metal Expansion, Primers, Etc.

- Size Chart:Size: Height: App.36Mm/1.41Inch

- As per Image

- Material: All Copper

- Package Includes:5 Pieces Propane Welding Nozzle

- Kindly Refer The Product Description Before Buying The Product.

Exceptional Heat and Spatter Resistance

Our copper welding nozzles are built to withstand intense thermal conditions, providing high resistance against heat and spatter. This makes them ideal for rigorous industrial welding, brazing, and soldering tasks that demand durability and reliability without sacrificing performance.

Versatile Torch Compatibility

Designed for flexibility, these nozzles are compatible with MIG, MAG, and TIG torches as per specific models. Whether the requirement is a cylindrical or conical shape, or standard or custom size, well ensure the right fit for your welding setup and process needs.

Superior Corrosion Resistance and Maintenance

The polished finish extends the lifespan of each nozzle by offering excellent protection against rust and chemical reactions. Routine upkeep is hassle-free, with an easy-clean design that supports frequent reuse for consistent operational efficiency.

FAQs of Welding Nozzle:

Q: How do I determine the correct welding nozzle for my MIG, MAG, or TIG torch?

A: Selection depends on your torch model and the specific welding application. Check compatibility guidelines for each nozzle variantcylindrical or conical shapes are available, along with standard or custom sizes to match your equipment and workflow.Q: What benefits does a polished copper surface provide in welding nozzles?

A: A polished surface finish enhances the nozzles corrosion resistance and simplifies cleaning, ensuring longer lifespan and consistent performance during industrial use.Q: When is it necessary to replace a welding nozzle?

A: Replace the nozzle when you notice excessive wear, deformation, or persistent clogging from spatter that affects performance, even after cleaning. Routine inspections during maintenance will help identify the right time for replacement.Q: Where are these copper welding nozzles commonly used?

A: They are widely used in industrial environments across India for welding, soldering, and brazingespecially in manufacturing, fabrication, and repair operations. Distributors, manufacturers, suppliers, and traders frequently utilize these nozzles for their reliability and versatility.Q: What is the cleaning process for maintaining the nozzles performance?

A: Simply remove the nozzle from the torch and use a wire brush or mild solvent to clear out spatter and debris. The polished surface ensures residues are easily removed, supporting ongoing nozzle reusability.Q: How does high thermal conductivity benefit welding applications?

A: High thermal conductivity in copper ensures rapid heat dissipation, preventing nozzle overheating and maintaining a stable arc. This contributes to safer and more consistent weld quality during prolonged use.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Welding Accessories Category

Welding Hose Pipe

Price 140 INR / Meter

Minimum Order Quantity : 50

Product Type : Welding Safety Equipment

Usage : Industrial use

Special Features : Welding hose pipe

Welding Hood

Price 175 INR / Piece

Minimum Order Quantity : 100 Pieces

Product Type : Face Safety

Usage : Industrial use

Special Features : Welding Safety

Welding holder

Price 130 INR / Piece

Minimum Order Quantity : 100 Pieces

Product Type : security safety

Usage : Industrial use

"We want inquiries from North India only"

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free